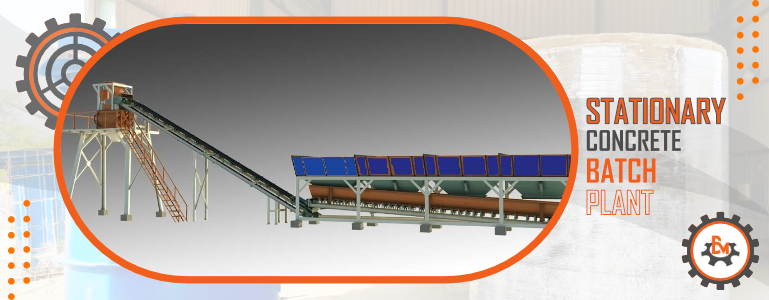

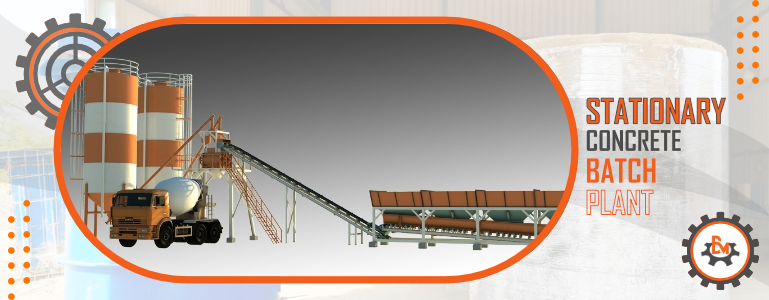

Stationary concrete Batching plant is the new type of concrete batching plant that designed and produced by our company which have adopted advanced technology and scientific achievements from domestic and abroad, combine our abundant experience of produce batching plant. It is one of the best concrete batching plant in India. Our Plants are made to meet the requirement of market needs. Having unique mixer unit, and state of the art machine design, combined with latest PLC based control panel we have made the concrete work simple and hassle free. This new generation of batching plants are easy to operate and having least operation and maintenance cost.

Our Plant include functions like batching system, electric weighing system, aggregate lifting system, mixing system unit. So it is convenient to move and easy to install. It is your best choice for Stationary concrete plant operations in various constructions such as highway, railway, architecture, municipal engineering, bridge, port and hydropower station.

The B. M. gives best Quality Stationary Concrete batching plat at best price.

- Available in 12/15/18/20/25m3/hr. capacity.

- Mixer – Twin Shaft or PAN type, for continuous mixing.

- Mixer having Electronic load Cell type weighing system.

- Loading of Aggregate/Sand Hoppers by Wheel loader/ Conveyors/ Manually.

- Inbuilt Water and Additive tank.

- Fully Automatic Electronic operation with integrated PLC / PC Control and Remote function.

- Entire plant can be transported in single 40 feet trailer.

- Rigid construction of main chassis; fabricated from rolled mild steel material.

- Replaceable liner Tiles and Tips in to the mixer.

- Fully automatic plant with Electronic weighing of Agg./Sand/Water/Cement.

- PLC based control panel with integral computerized batch controller accommodates 99 different mix recipes.

- Maximum weighing accuracy.

- Plant only requires Electric Power Supply, Water Piping, Aggregate/Sand feeding.

- Heavy Robtus design.

- Plant can be erected & commissioned within two days.

- Remarkably cost efficient.

- Plant operation is very silent & with clean surrounding.

- Very fewer maintenance of plant, due to less wear and tear parts.

- Complete plant can be transported in one 40 foot trailer.

- Online Printing System.

- Discharge Belt Conveyor.

- Fly Ash Feeding System

- Cement Storage Silo

- Computer SCADA System with software.

- Touch Screen with provision of USB for data back up.

| Type | BM-30 | BM-40 | BM-60 | BM-75 |

| Max. Productivity (m3/h) | 30 | 40 | 50/60 | 75 |

| Concrete Mixer | BM500 | BM750 | BM1000 | BM1500 |

| Concrete Batching Machine | PLD800 | PLD1200 | PLD1600 | PLD2400 |

| Discharging Capacity (L) | 500 | 750 | 1000 | 1500 |

| Total Installed Capacity | 45 | 47 | 109 | 145 |

| Motor Power (KW) | 18.5 | 30 | 37 | 45 |

| Aggregate Weighing Range (KG) | 1800 | 2500 | 3000 | 3800 |

| Cement weighing Range (KG) | 205 | 400 | 600 | 1000 |

| Maximum Size of Aggregate (MM) | 80 | 80 | 80 | 80 |

| Discharge Height (MM) | 3800 | 3800 | 3800 | 3800 |